Rice Milling Machine: The Key to High-Quality Rice Production

Rice is one of the most important staple foods in the world, consumed by billions across Asia, Africa, and parts of Latin America. As demand for rice continues to rise, the need for efficient, precise, and modern processing has never been more urgent. This is where the Rice Milling Machine plays a vital role. It transforms raw paddy into polished, market-ready rice through a series of mechanical operations. For rice millers, agricultural entrepreneurs, and food industry investors, understanding the value of rice milling machines is essential for maximizing productivity and profitability.

What is a Rice Milling Machine?

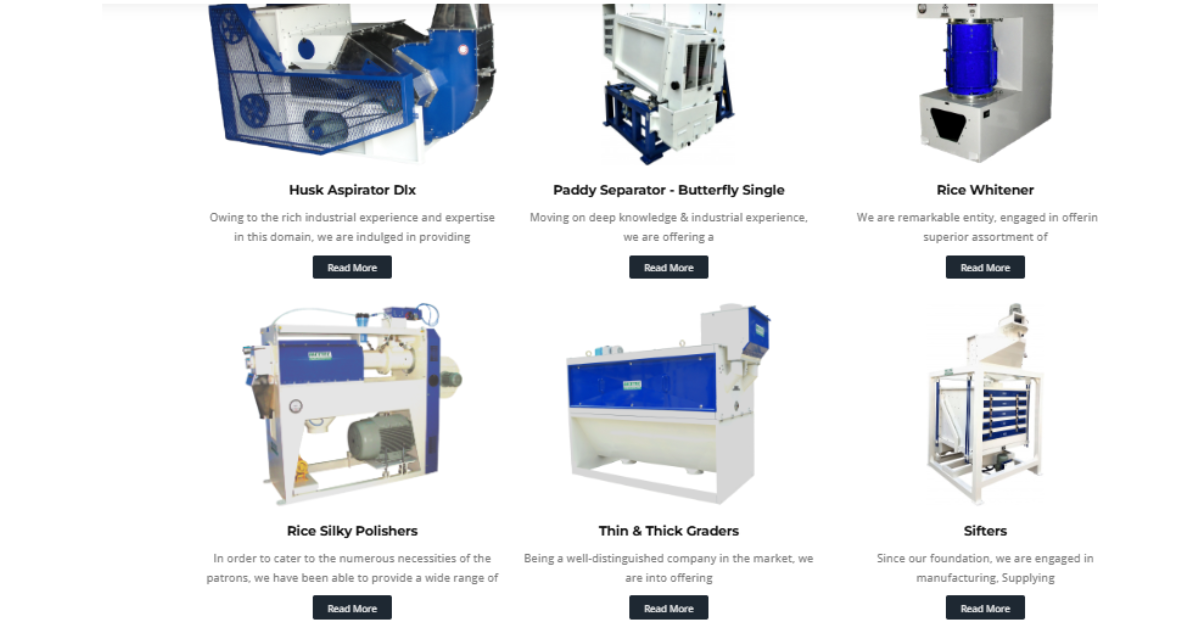

A Rice Milling Machine is a type of equipment used to process harvested paddy into edible white rice. It performs several critical steps including cleaning, dehusking, separating, whitening, polishing, grading, and packaging. Whether used in small-scale operations or large commercial mills, the rice milling machine ensures uniformity, minimizes waste, and maintains hygiene during the entire milling process. Modern rice milling machines offer automation, precision, and high-speed performance, making them indispensable in today’s agricultural landscape.

Main Functions of a Rice Milling Machine

The rice milling process involves multiple stages, each carried out by a dedicated component or integrated system within the machine. These include:

Pre-Cleaning

This function removes straw, dust, stones, and other impurities from the raw paddy. It is the first step to ensure quality and protect the machine from damage.

Dehusking

The machine removes the outer husk layer from the paddy using rubber rollers or friction-based methods. This results in brown rice.

Paddy Separation

After dehusking, the machine separates the unhusked grains from the brown rice using density-based separation techniques.

Whitening

The whitening section removes the bran layer from brown rice to produce white rice. This is typically done through abrasion or friction between the rice grains and milling surfaces.

Polishing

To improve appearance, the machine polishes the white rice to give it a smooth and shiny surface, making it more appealing to consumers.

Grading

The grading unit classifies rice based on size and length. Broken grains are separated from whole ones to meet commercial standards.

Color Sorting

Advanced rice milling machines include color sorters that use optical sensors to detect and remove defective or discolored grains.

Packing

The final processed rice is automatically weighed and packed into bags for retail or bulk sale.

Benefits of Using a Rice Milling Machine

Higher Yield

Rice milling machines are designed to maximize head rice recovery while minimizing breakage. This increases the overall yield and profitability for millers.

Time and Labor Savings

By automating the entire process, rice milling machines reduce the need for manual labor and cut down production time significantly.

Consistent Quality

The automated process ensures uniform grain size, appearance, and texture, which is crucial for market acceptance and export standards.

Hygiene and Safety

Made from food-grade materials, rice milling machines maintain hygiene throughout the process, reducing contamination risks.

Energy Efficiency

Modern machines are engineered for minimal energy consumption, contributing to lower operational costs and environmental sustainability.

Versatility

Most rice milling machines can handle various rice types such as long grain, short grain, parboiled, and basmati, making them suitable for diverse markets.

Choosing the Right Rice Milling Machine

When investing in a rice milling machine, several factors should be considered to ensure the right fit for your production goals.

Production Capacity

Select a machine that matches your daily or hourly milling requirements. Overcapacity can waste resources, while undercapacity can create bottlenecks.

Level of Automation

Machines range from manual to semi-automatic to fully automated systems. Fully automated machines are ideal for large operations with higher efficiency needs.

Rice Type

Consider the type of rice you plan to process. Machines should have the flexibility to handle different varieties and moisture content levels.

Build Quality

Durability matters. Choose machines built with high-quality materials like stainless steel, which resist corrosion and wear over time.

Supplier Reputation

Partner with a reputable manufacturer who offers installation support, warranty coverage, and after-sales service.

Budget

While initial costs may be high, long-term savings on labor, maintenance, and energy often justify the investment.

Ricetec Machinery: Trusted Name in Rice Milling

Ricetec Machinery has earned a reputation for delivering reliable, efficient, and technologically advanced rice milling machines. Whether you’re starting a new mill or upgrading existing operations, Ricetec offers complete milling solutions tailored to your business needs. Their machines are designed for high-capacity milling with features like digital controls, customizable settings, and integrated polishing and grading. With a commitment to innovation and customer satisfaction, Ricetec is a preferred choice for millers across the globe.

Innovations in Modern Rice Milling Machines

Today’s rice milling machines are no longer simple mechanical tools. They integrate advanced features that improve accuracy, performance, and ease of use.

Digital Automation

Machines now include programmable logic controllers (PLCs) and touch-screen panels, allowing operators to monitor and adjust settings in real time.

IoT Integration

Internet of Things (IoT) features enable remote monitoring, predictive maintenance, and performance analytics, ensuring maximum uptime.

AI-Based Sorting

Artificial Intelligence is used in color sorters to enhance the accuracy of grain separation, reducing waste and improving final output quality.

Modular Design

Some machines offer modular components, allowing users to add or upgrade functions such as polishing, grading, or packing as the business grows.

Maintenance Tips for Rice Milling Machines

Proper maintenance extends the life of your rice milling machine and ensures consistent performance.

-

Clean all parts daily to prevent buildup of husk, bran, or dust

-

Inspect belts, bearings, and screens for wear and replace them as needed

-

Lubricate moving parts according to the manufacturer’s schedule

-

Check electrical systems regularly for faults or loose connections

-

Calibrate sensors and digital panels to maintain processing accuracy

Frequently Asked Questions (FAQ)

What is the purpose of a rice milling machine?

A rice milling machine is used to convert harvested paddy into polished white rice by removing the husk, bran, and sorting grains by size and quality.

Is it necessary to have a color sorter in a rice milling machine?

For commercial and export-quality rice, a color sorter is essential to remove defective or discolored grains and improve the product’s appearance and market value.

How much does a rice milling machine cost?

The cost varies based on capacity, automation level, and brand. Basic models may start at a few thousand dollars, while industrial-grade machines can cost significantly more.

Can one machine handle all types of rice?

Modern machines are often versatile and can be adjusted to handle different rice types including long grain, parboiled, and basmati rice.

Why choose Ricetec Machinery for rice milling equipment?

Ricetec Machinery offers advanced, durable, and efficient rice milling machines backed by technical expertise, customization options, and excellent after-sales support.

Conclusion

A Rice Milling Machine is the backbone of modern rice production. It delivers consistent quality, saves time, reduces labor, and maximizes yield, making it an essential asset for millers, exporters, and rice processors. Whether you’re operating a small mill or a large-scale facility, the right rice milling machine can transform your business. With companies like Ricetec Machinery offering state-of-the-art equipment and comprehensive solutions, investing in a high-performance rice milling system is a smart move toward long-term success in the competitive rice industry.